%FPS bot testing

close all;

offsetAngles = [0 0 0 0 0];%Just the difference in angle between frontmost motor and forward direction.

motorCounts = [3 4 5 6 7];

motorAngles = 2*pi./motorCounts;

for j = 1:numel(motorCounts)

mvec = zeros(motorCounts(j),2);

for k = 1:motorCounts(j)

mvec(k,:) = [cos(offsetAngles(j)+(k-1)*motorAngles(j)) -sin(offsetAngles(j)+(k-1)*motorAngles(j))];

end

resolution = 10000;

theta = linspace(0,2*pi,resolution)';

directionVector = zeros(resolution,2);

directionVector(:,1) = cos(theta);

directionVector(:,2) = sin(theta);

%Speed

mag = zeros(resolution,1);

currentMag = zeros(motorCounts(j),1);

for k=1:resolution

for i=1:motorCounts(j)

currentMag(i) = abs(mvec(i,:)*directionVector(k,:)');

end

mag(k) = max(currentMag);

end

figure;

plot(theta,mag);

ylabel('Normalized speed magnitude');

xlabel('Direction (radians)');

title(['Normalized speed magnitude vs. direction, ' num2str(motorCounts(j)) ' motors']);

%Torque

motorUse = zeros(resolution,1);

for k=1:resolution

for m=1:motorCounts(j)

motorUse(k) = motorUse(k)+abs(mvec(m,:)*directionVector(k,:)');

end

end

figure;

plot(theta,motorUse);

ylabel('Equivalent motor usage (# of motors)');

xlabel('Direction (radians)');

title(['Motor usage vs. direction, ' num2str(motorCounts(j)) ' motors']);

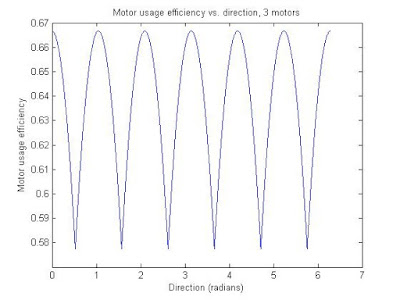

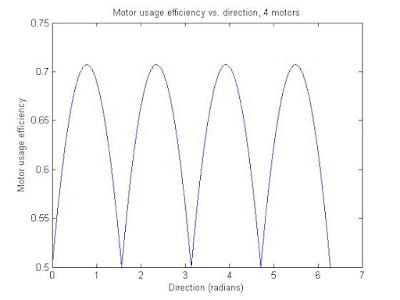

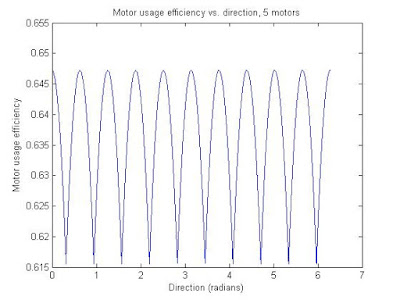

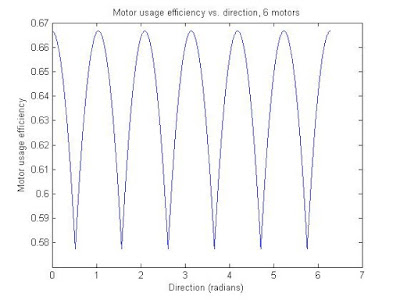

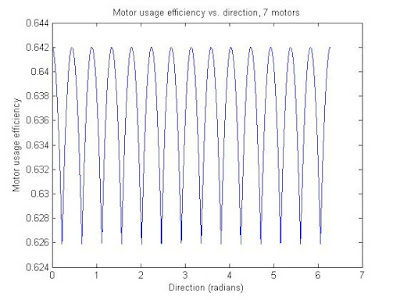

figure;

plot(theta,motorUse/motorCounts(j));

ylabel('Motor usage efficiency');

xlabel('Direction (radians)');

title(['Motor usage efficiency vs. direction, ' num2str(motorCounts(j)) ' motors']);

end